The New Era of Sustainable Fabrics in Uniforms and Workwear

BY BRYAN JINNETT

In recent years the global apparel industry has made significant advances in fabric science with a strong shift toward sustainability and circularity. Corporate apparel and workwear are beginning to benefit from this evolution as new fibers and weaving technologies replace older chemical based finishing methods. Uniforms have traditionally been required to perform under demanding daily use with long life cycles. The result has been a heavy reliance on polyester and chemical treatments designed for wrinkle resistance, moisture wicking, and stain release. That landscape is changing quickly.

New Sustainable Fibers Emerging

Several new categories of sustainable textile materials are beginning to make their way into commercial apparel. Notable groups include:

Regenerative Cellulosic Fibers

Modern cellulosic fibers are derived from renewable plant sources using closed loop production methods that reduce waste and capture solvents for reuse. These fibers provide natural breathability, next to skin comfort, and superior moisture management without chemical coatings.

Recycled Synthetic Fibers

Traditional polyester consumes fossil resources and does not break down at end of life. Recycled polyester offers a more circular solution sourced from reclaimed plastic and textile waste. Advancements in mechanical and chemical recycling have improved yarn quality making them suitable for tailored garments and high touch uniform environments. Recycled nylon has also become more available and presents similar circular benefits for performance garments and outerwear.

Bio Based Synthetics

Bio based synthetics replicate the performance characteristics of nylon and polyester but are derived in part from renewable plant sources such as corn or castor beans. These materials reduce reliance on petroleum inputs while maintaining durability and shape retention which are important in workwear applications.

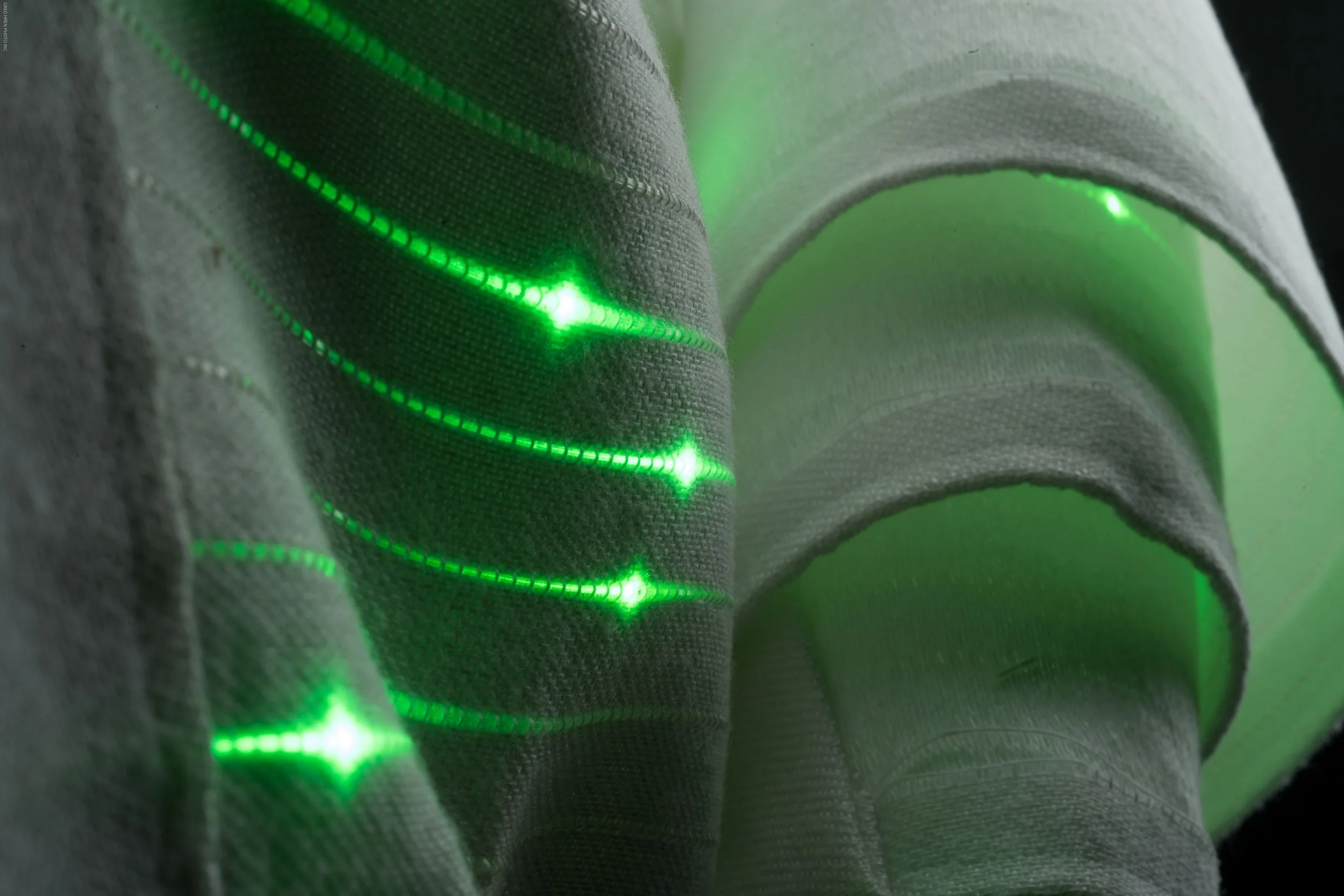

Natural Stretch and Performance Through Weaving

Historically many performance benefits in uniforms were achieved through chemical finishing. Moisture wicking was applied as a topical treatment. Wrinkle resistance was achieved with resins. Stretch was added through elastane blends that introduced microplastics. Today mills are designing performance directly into the yarn construction and weaving method which reduces or eliminates the need for chemical finishes.

For example:

High density weaving techniques create natural wrinkle resistance

Engineered yarn cross sections enhance moisture transport away from the skin

Mechanical stretch yarns provide elasticity without elastane

Blend constructions combine the cool touch of cellulosics with the durability of recycled synthetics

These innovations allow fabric performance to endure wash after wash instead of fading when chemical treatments wear off.

Stronger Standards and Safer Materials

Benefits for the People Wearing the Clothing

Uniform programs impact real people every day. When pilots, gate agents, hotel staff, drivers, maintenance crews, and food service teams are required to wear a garment for eight to ten hours daily the fabric matters. Sustainable and technologically advanced fabrics provide meaningful benefits:

Improved comfort due to breathability and moisture control

Softer hand feel for long shifts

Better thermoregulation that keeps the body cooler in heat and warmer in cold

Reduced skin irritation due to lower chemical dependency

Lighter fabrics without sacrificing durability

Longer lasting performance that holds up through repeated laundering

Why This Matters for Corporate Programs

Uniforms and workwear live longer than fashion garments and therefore represent a meaningful part of sustainability strategies. Introducing circular materials, recycled inputs, and bio based fibers into uniform programs can reduce environmental impact without compromising performance. Combining these fibers with intelligent weaving blends that remove chemical reliance creates a more comfortable garment for the wearer and a more responsible product for the organization.

At JWE we continue to evaluate and develop these fabric platforms for adoption across multiple industries. Sustainability should enhance performance and comfort, not limit it. The fabric technologies emerging today are proving that both goals can coexist.